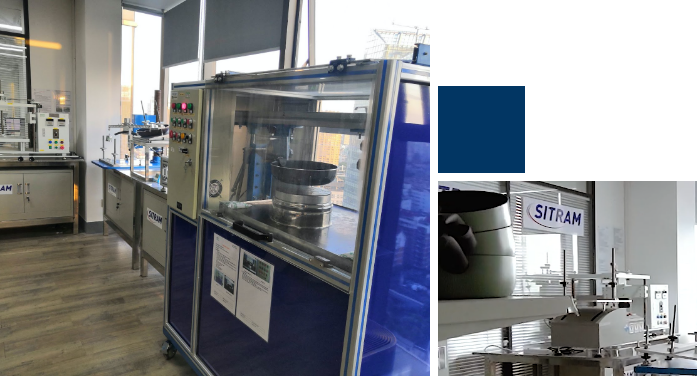

The SITRAM lab

A lab to test the performance and durability of Sitram products

Discover the tests we perform in our laboratory on a daily basis

Hover over the numbers of the legend to learn more

about the various tests conducted

Cookware interior

• Anti-adhesion before/after abrasion

• Heat distribution

• Boiling time

• Useable capacity

• Heating surface

• Corrosion resistance

• Interior scratch resistance

Cookware exterior

• Exterior scratch resistance

• Cookware thickness

Cookware base

• Thermal shock resistance

• Base thickness

Cookware handle

• Fatigue resistance

• Torque resistance

• Bending strength

The mission of our in-house laboratory is to improve our product lines with respect to:

The mission of our in-house laboratory is to improve our product lines with respect to:

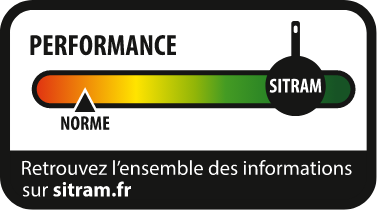

- performance (for example: the time it takes to boil 1 liter (4.22 cups) of water),

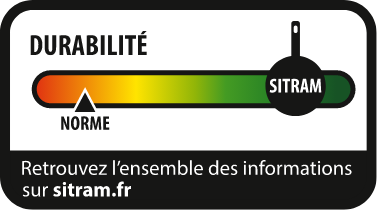

- durability (for example, the wear resistance of the coating).

To help our customers find the right product to suit their needs and budget, we have provided visual indicators based on the results of various tests;